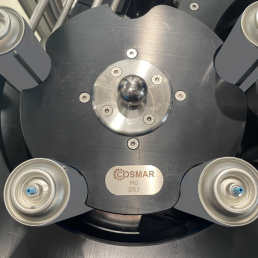

AUTOMATIC CONTINUOUS ROTARY PROPELLANT FILLING MACHINE

This machines is electronically managed and suitable for flammable propellant.

This machine is equipped with 8 hydraulic metering cylinders that do not require air to perform the filling of the propellant through crimped valves.

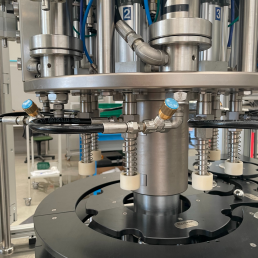

The operating cycle of the metering cylinders occurs in two phases:

• Refilling phase: the propellant is delivered to the upper and the lower chambers of the metering cylinder through a rotating manifold. The propellant pressure inside the two chambers is generated by the high-pressure pump and considering that the internal area of lower chamber of cylinder is larger than the area of upper chamber due to the rod section, the piston moves up to recharge.

• Injection phase: the filling head is moved down on the can, and a mechanical valve is opened. In this way the lower chamber of the metering cylinder is in communication with the inner part of the can. The pressure of the upper chamber moves down the piston that supplies the quantity of the propellant, charged into the lower part of the chamber, to the can.

A limit switch is installed at the end of the stroke of the metering cylinder to stop the filling phase and restart the recharge one.

This machine is usually able to fill till 350 ml or more depending on the size of the metering cylinders installed. The production capacity could range between 100 to 200 cpm depending on the configuration.

The High-pressure pump can be managed in order to electronically adjust the pressure between 30 and 55 bars, by using the HMI installed on board.

This machine can be installed in existing line by connecting the conveyor section of the customer.